Custom t-shirt printing has become an increasingly popular method for individuals and businesses to showcase creativity, build brands, and celebrate events. Whether you’re designing shirts for a company, a sports team, a band, or a personal project, the process of custom t-shirt printing allows for unique expression and targeted messaging. With advancements in printing technologies, multiple methods are available today, each suited for different needs, budgets, and design goals.

This article explores the types of custom t-shirt printing and breaks down the process from design to finished product.

Why Choose Custom T-Shirt Printing?

Custom t-shirt printing is a go-to choice for a variety of reasons:

- Personal Expression: Share a message, artwork, or humor.

- Business Promotion: Branded merchandise and staff uniforms.

- Special Events: Family reunions, bachelor parties, birthdays, etc.

- Fundraising and Awareness: Non-profits and campaigns.

Whatever your goal, choosing the right printing method is essential to achieve the desired look, durability, and cost-effectiveness.

Types of Custom T-Shirt Printing

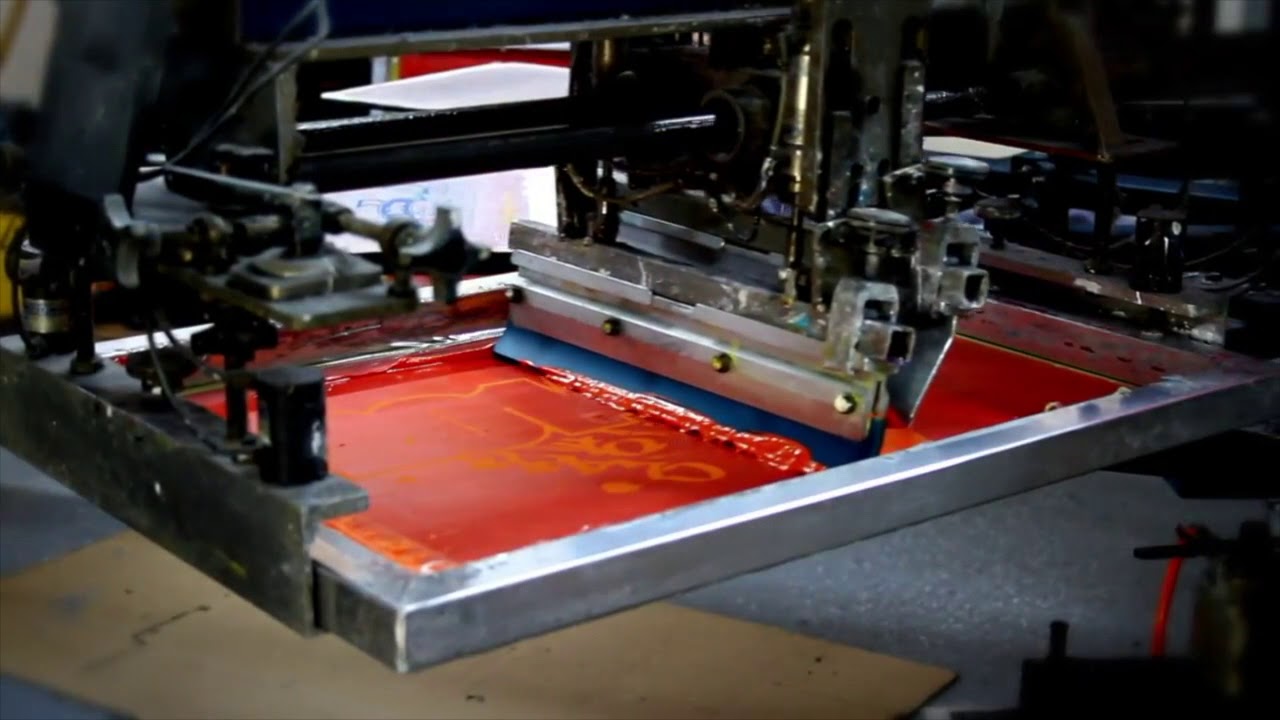

1. Screen Printing

Best for: Bulk orders, bold designs with few colors.

Screen printing, also known as silk screening, is one of the oldest and most widely used methods. It involves creating a stencil (or screen), and pushing ink through it onto the fabric.

Pros:

- Vibrant, long-lasting prints.

- Cost-effective for large batches.

Cons:

- Not ideal for detailed or multicolor designs in small quantities.

- Setup time and cost can be high.

2. Direct-to-Garment (DTG) Printing

Best for: Full-color designs, photo-realistic images, small batches.

DTG printing uses a special inkjet printer to apply water-based inks directly onto the fabric. The results are smooth, colorful prints with minimal setup.

Pros:

- Ideal for complex designs with many colors.

- Soft feel and breathable print.

Cons:

- Works best on 100% cotton shirts.

- Less durable than screen printing over time.

3. Heat Transfer Printing

Best for: One-off prints, DIY projects, or on-demand fulfillment.

This method involves printing a design onto a special transfer paper and then using heat to apply it to the fabric.

Pros:

- Easy for small runs or customized items.

- Works on a variety of fabrics.

Cons:

- Less durable—designs may peel or crack with repeated washing.

- May feel heavy on the fabric.

4. Sublimation Printing

Best for: All-over prints on polyester or poly-blend shirts.

Sublimation uses heat to transfer dye into the fabric. The ink becomes part of the material itself, creating a smooth, vibrant design.

Pros:

- Permanent, fade-resistant prints.

- Great for full-coverage and bright designs.

Cons:

- Only works on light-colored polyester fabrics.

- Not suitable for cotton garments.

5. Vinyl Cutting

Best for: Simple text and graphics, such as sports numbers or slogans.

Vinyl printing uses a machine to cut out designs from colored vinyl sheets. These are then heat-pressed onto the shirt.

Pros:

- Durable and clean-looking designs.

- Great for personalization (e.g., names and numbers).

Cons:

- Not suitable for complex or multicolor artwork.

- The vinyl can feel stiff.

The Custom T-Shirt Printing Process

Here’s how custom t-shirt printing typically works:

Step 1: Design Creation

Start by creating a design using graphic software like Adobe Illustrator, Photoshop, or a free tool like Canva. Ensure your design has:

- High resolution (at least 300 DPI)

- Transparent background (for non-full-coverage prints)

- Correct dimensions for your chosen shirt size

Step 2: Choose the Printing Method

Your design, quantity, fabric type, and budget will determine the best printing method. For example:

- Screen printing for 100+ shirts with limited colors

- DTG for detailed or multicolor prints in small quantities

- Vinyl for simple text or logos

Step 3: Select the T-Shirts

Choose the garment style, color, and fabric. 100% cotton is great for DTG and screen printing, while polyester is needed for sublimation.

Popular choices include:

- Basic crew-neck tees

- V-necks

- Long sleeves

- Performance fabric tees

Step 4: Printing

Once everything is finalized, the printing process begins. Each method follows a specific workflow:

- Screen printing: Screens are created, ink is pushed through.

- DTG: The printer directly sprays ink on the shirt.

- Vinyl: Designs are cut and heat-pressed.

- Sublimation: Ink is heat-transferred into the fabric.

Step 5: Curing and Finishing

After printing, the shirts are heat-cured to set the ink and improve durability. A quality check ensures the prints are clean and aligned properly. Then, the shirts are folded and packaged.

Final Thoughts

Custom t-shirt printing is a powerful way to bring your creative vision to life—whether for personal use or business. With several printing methods available, each offering distinct advantages, there’s a solution for every type of design, budget, and volume requirement.

Understanding the types of t-shirt printing and the overall process allows you to make informed choices and achieve the best results. Whether you’re ordering a few custom tees or launching a full-fledged clothing line, the possibilities are endless with custom printing.